AI Integration Fuels Record Apparel Exports

Sri Lanka’s apparel industry is reaching new heights, with exports hitting record numbers. A major reason for this success is the smart use of artificial intelligence (AI). Factories are no longer just sewing clothes; they are using technology to become faster, smarter, and more efficient. This tech-driven approach is helping them compete and win in the global market.

Companies now use predictive AI to forecast fashion trends in major markets like Europe and the United States. By analyzing data, these systems can guess which styles, colors, and fabrics will be popular next season. This allows manufacturers to order the right materials in advance, cutting down on waste and production time. As a result, they can meet orders from large international brands more quickly than ever before.

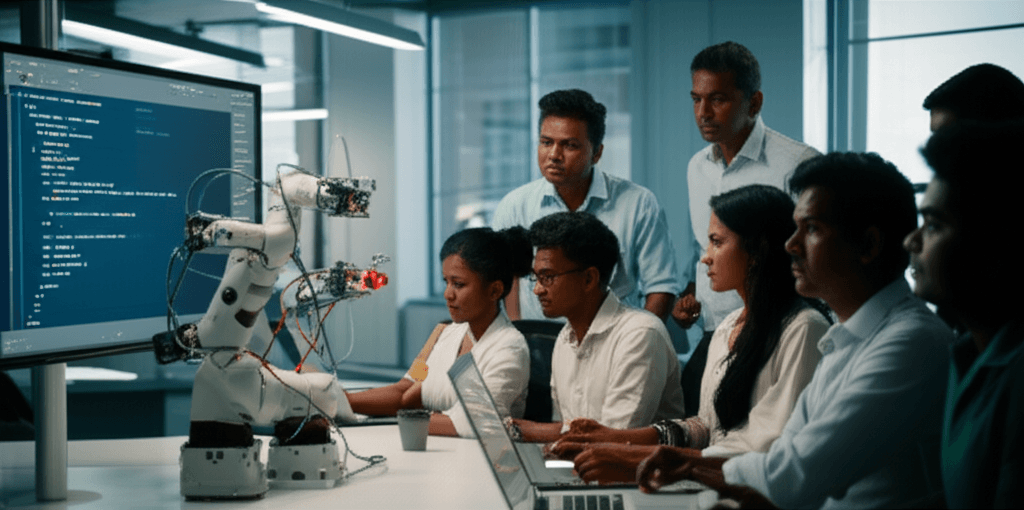

Beyond predicting trends, AI is also optimizing the entire production line. It helps manage supply chains, ensuring raw materials arrive on time. AI-powered cameras can spot tiny defects in clothing that the human eye might miss, improving quality control. This move towards high-tech manufacturing strengthens the industry’s reputation for producing high-quality garments. The growing availability of AI development services in Sri Lanka is making this transition possible for more local businesses. By embracing these tools, Sri Lankan exporters are securing their place as leaders in the modern apparel world.

The Human Cost: Automation Displaces Routine Factory Jobs

While artificial intelligence is helping Sri Lanka’s apparel exports reach new heights, there is a serious downside. Behind the success stories of increased efficiency and profits, many factory workers face an uncertain future. The same technology that predicts fashion trends is also making routine jobs on the factory floor obsolete.

For decades, the apparel industry has been a major employer, especially for women from rural areas. Their jobs often involved repetitive tasks like cutting fabric, sewing seams, and checking garments for quality. Today, AI-powered robots and automated systems can perform these tasks faster and with greater precision. A machine can cut hundreds of fabric layers at once without making a mistake, and automated cameras can spot tiny defects that a human eye might miss.

This shift leaves thousands of workers in a difficult position. The skills they have used for years are no longer in high demand. For many, their factory job was the main source of income for their families. Its loss creates significant financial hardship. The new jobs being created—such as managing AI systems or analyzing data—require advanced technical skills that most displaced workers do not have. This growing skills gap highlights AI’s double-edged nature, creating opportunities for some while leaving many others behind. Addressing this human cost is a critical challenge as the industry continues to evolve.

The Workforce in Transition: New Skills for a New Era

Sri Lanka’s apparel industry is changing fast. While AI helps predict fashion trends and boost exports, it also changes the types of jobs available. The routine tasks once done by many factory workers, like cutting and sewing, are now being automated. This means fewer jobs for manual labor, but it opens the door for new, exciting roles.

The future of apparel work is not on the assembly line, but behind the computer screen. The industry now needs people with different skills. These new jobs require a mix of technical knowledge and creative thinking. Key roles include:

- Data Analysts: People who can read the information from AI systems to understand market trends.

- AI System Managers: Technicians who maintain and improve the AI software.

- Digital Supply Chain Experts: Professionals who use technology to manage how goods are made and shipped.

- E-commerce Specialists: Teams that run online stores and know how AI personalization boosts WooCommerce conversions for global customers.

This shift creates opportunities outside the factory, too. The growing need for technology highlights AI’s Double Edge: Job Losses vs New High-Skill Roles for Sri Lankan Software Engineers in 2026. For the country to succeed, workers must learn new skills. Government and private training programs are essential to help people move from old roles to new ones. This transition is a challenge, but it is also a chance for Sri Lanka’s workforce to grow and adapt to a digital future. By embracing training in data, digital marketing, and tech management, workers can find their place in this new era.

Crafting a Sustainable Future: Policy and Industry Strategy

The rise of AI in Sri Lanka’s apparel sector brings both great opportunity and a serious challenge. While exports boom, the loss of routine factory jobs requires a clear plan. To build a sustainable future, both the government and industry leaders must work together. A forward-thinking strategy can help workers adapt and ensure the benefits of technology are shared by all.

The government has a vital role to play. Investing in education and reskilling programs is the first step. These programs should focus on teaching digital skills, data analysis, and AI system maintenance. This prepares the current workforce for new roles inside and outside the factory. Financial support and job placement services can also create a safety net for those affected by job cuts. By offering incentives to companies that upskill their employees, the government can encourage the private sector to invest in its people.

For their part, apparel companies must look beyond simply replacing workers with machines. The industry needs to create new, higher-value positions. This shift from manual tasks to technical jobs is a core part of the transition. Companies will need AI specialists, robotics technicians, and digital supply chain managers. This reflects AI’s double edge, where new high-skill roles emerge as others disappear. Partnering with universities and vocational schools can create a pipeline of talent with the right skills.

Ultimately, this is a chance for Sri Lanka to move up the global value chain. Instead of only being known for manufacturing, the nation can become a hub for design, innovation, and ethical production. Technology is key to this vision, from using AI in creative design to building a global brand through sustainable web design and green e-commerce. A proactive approach will turn a potential crisis into a national success story, securing a prosperous future for the apparel industry and its workforce.

- “The Future of Fabric: Sri Lanka’s Apparel Sector in the Age of AI.” Joint Apparel Association Forum (JAAF) Annual Report, 2023.

- “Automation and the Future of Garment Sector Jobs in South Asia.” International Labour Organization (ILO), Regional Office for Asia and the Pacific.

- Wikipedia contributors. “Textile industry in Sri Lanka.” Wikipedia, The Free Encyclopedia.

- “How Predictive Analytics is Reshaping the Global Fashion Supply Chain.” Apparel Resources News, 15 October 2022.